Building a Professional Mascot

ProMo begins the construction of your custom costume by taking the design you approved and creating detailed pattern pieces. These pattern pieces are carefully maintained, logged and stored in the event you need new or additional mascots made from your design in the future. It is from these pattern pieces that we can produce not only a single mascot costume but hundreds or even thousands as you need for your events, marketing or photo shoots. From these pattern pieces, we begin working with the construction materials to bring your custom character to life.

ProMo begins the construction of your custom costume by taking the design you approved and creating detailed pattern pieces. These pattern pieces are carefully maintained, logged and stored in the event you need new or additional mascots made from your design in the future. It is from these pattern pieces that we can produce not only a single mascot costume but hundreds or even thousands as you need for your events, marketing or photo shoots. From these pattern pieces, we begin working with the construction materials to bring your custom character to life.

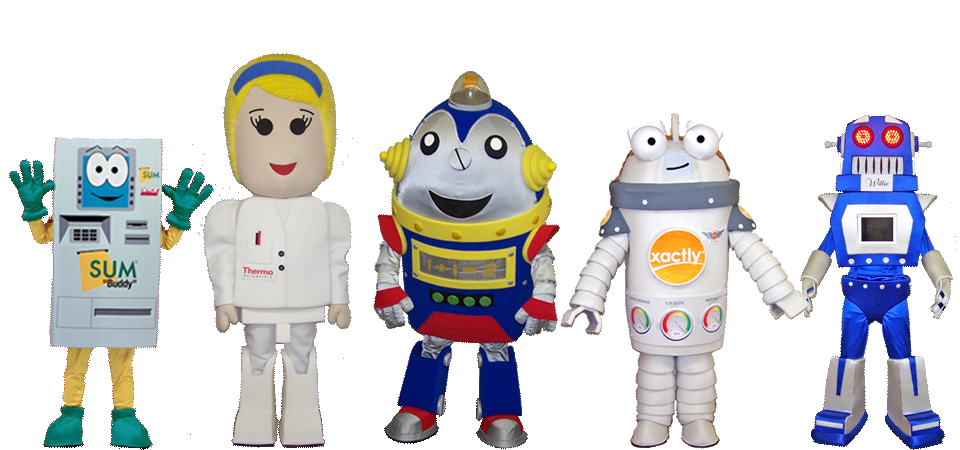

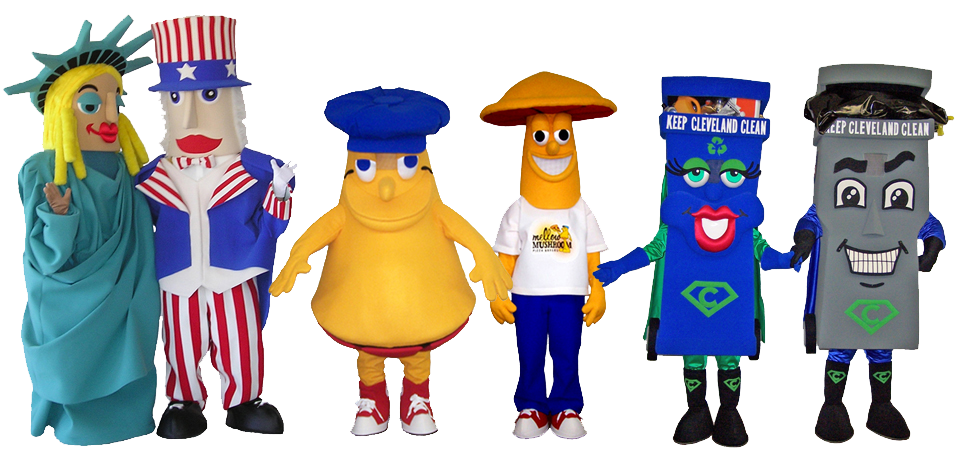

The first piece we focus on is the head of your character or mascot which is constructed of lightweight, industrial foam; sculpted and formed into the shape required. In utilizing our methods, we are able to produce extremely large yet durable character heads while minimizing the weight and strain on the actor inside. In the event the head of the mascot is accidentally crushed, our techniques and methods allow them to usually spring back into shape as if nothing happened holding their shape for years to come. Internally we provide adjustable head harnesses and helmets for the actors for maximum stability, control and comfort.

After the head is formed we focus on the facial features and aspects, adding them according to the design and artwork provided and approved by you. Typically this will include vision and ventilation through color screened areas of the eyes and/or mouth so as not to detract from the creation. There are times however in which a screened panel may be utilized for design purposes. After the mascot’s head is completed, we apply the various fabrics and imitation furs as applicable to complete the costume and move on to the body work.

After the head is formed we focus on the facial features and aspects, adding them according to the design and artwork provided and approved by you. Typically this will include vision and ventilation through color screened areas of the eyes and/or mouth so as not to detract from the creation. There are times however in which a screened panel may be utilized for design purposes. After the mascot’s head is completed, we apply the various fabrics and imitation furs as applicable to complete the costume and move on to the body work.

Depending on the design, additional shaping and sculpting may be performed for the body to meet your needs and the needs of the actor. This can entail lightweight sculpted foam for the inner body worn under the costume or by sewing in polyester fiber fill material into the costume itself. For one-piece body and head mascots, we utilize lightweight  sculpted foam for the entire shape, with the various fabrics on the outer shell using sublimation to replicate logos and designs. Once the body and head are completed, it’s time to move on to the mobility of the mascot because a complete mascot should be able to move freely and comfortably without detracting from the character.

sculpted foam for the entire shape, with the various fabrics on the outer shell using sublimation to replicate logos and designs. Once the body and head are completed, it’s time to move on to the mobility of the mascot because a complete mascot should be able to move freely and comfortably without detracting from the character.

Normally, we utilize the same fabric of the mascot body to create the arms and legs of the costume to ensure the creation is completely in character with the design. After all, imagine having an awesome mascot for your sports team and the actor is wearing normal everyday jeans and walking around as a tiger. It wouldn’t be right!

The same can be said for hands and feet, our approach is a four fingered hand with padding to accentuate the shape to allow the actor to grasp items, shake hands and even sign autographs. The feet are constructed of sculpted, lightweight but durable foam and covered with fabrics with internal slippers and a completed with long-life rubber soles to ensure safety and comfort while having mobility. For cleaning, the slippers are easily removed and can be replaced as needed.

ProMo takes pride in making a mascot or costume and we take actor comfort and safety into consideration in our process every step of the way. During the whole process, we ensure you are kept up-to-date with information, pictures and details as to how the construction is going and timeframes on completion of the various stages.

If you’re ready to take the next step, call us at 740-383-5176 today to get started or contact ProMo Costumes online!

Your mascot awaits!